Overview - Revised 2019

FCX Defined

The FCX Oil Fired Condensing “Boiler” is officially classified, certified, and labeled as an Oil-Fired Water Heater in accordance with UL-732, and in accordance with IMC Section 1002.1&2 Water heaters utilized for space heating. It is not subject to IMC 1004 Boilers and UL-726.

How Boilers Work.

For our purposes a boiler is defined as a heating device for residential or commercial structures. It heats water that is distributed throughout the structure to warm and make it comfortable. These are commonly referred to as hydronic systems. While other systems exist that actually “boil” the water and use steam to distribute the heat, these boilers and systems do not. Here are two links that will expand on these topics. <Boiler> <Hydronic>

<top>

Principles

Heat Recovery

In order to understand how these systems work, we must first understand how heat is made and then recovered. The boiler consists of a steel vessel that contains water. The water is heated by applying the burned hot fuel flue gases to the boiler jacket with this heat transferred to the water inside the boiler. The heated water is then pumped to the heat-emitters such as baseboard heaters or radiant slab, and the cooled flue gas then passes up the chimney and exits the structure. These boilers can also heat domestic hot water (DHW) for use in bathing, washing, etc.

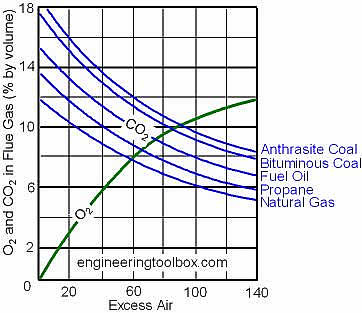

While the greater the difference in flue gas temperature and the media being heated, flue gas temperatures are affected by other factors. Fuel oil burns at about 3,800 degrees, but the actual flue gases are reduced in temperature to about 2000 degrees, by excess air which is needed to produce a proper burn. The greater the excess air, the lower the flue gas temperature and thus the lesser the efficiency. CO2 is inversely proportional to excess air.

There are two processes in recovering heat from the combustion flue gases. The first is described above, where the major products of combustion (the flue gases) are carbon dioxide (CO2) and water vapor (H2O). In a conventional boiler, the normal temperature of the flue gas exiting is 350° to 450°. The heat recovered by lowering the flue gas temperature is called sensible heat. This is where the heat extraction of a conventional boiler stops, and the maximum efficiency a conventional boiler can achieve is about an AFUE of 87% with a CO2 content of 13.5%. This is further reduced as it is common to tune the conventual boiler to about 10.5 to 11.5% CO2, further reducing the initial flue gas temperature.

In the second process (which only condensing boilers use) the flue gas temperature is reduced even further, with additional heat exchange, to the point where the water vapor in the flue gasses begins to condense. This change from vapor to liquid gives up heat. When water changes state from a gas to a liquid (goes from a gas at 212° to liquid at 212°), it gives off heat that is absorbed by the water in the boiler, just as you must add heat to liquid water to boil it, the reverse process allows the boiler to absorb this heat. This is called recovering the latent heat of vaporization (latent from the Greek root word meaning hidden). In addition to recovering latent heat, it also recovers more sensible heat as stack temperatures are also further reduced. Stack temperatures are typically reduced to at least 150° F or below. This results in efficiencies around 93%. However efficiencies of 97% to 98% can be reached through enhanced reduction of flue gas temperatures.

So, the condensing boiler gives us the double whammy of recovering latent heat through condensing, and even more sensible heat through lowering the stack temperature further. However, benefits do not come without some complications. We must in turn learn how to handle lower stack temperatures and the water produced inherent to the condensing process both in the boiler and in the stack.

<top>

Conventional Boilers

Typically, conventional boilers heat water to higher temperatures than condensing boilers. This has been done in the past for several reasons. With hotter water (anywhere from 140° to 190°), heat recovery is faster (the room heats up more quickly), fewer emitters (such as baseboard heaters) are required, and boiler efficiency has not been a concern in the past when fuel costs were low.

But the main reason and governing factor in conventional boiler design is that if temperatures are lowered it will start to condense. Because conventional boilers are not designed to condense, the slightly acidic condensate will destroy the boiler and the stack within a year or so.

An interesting fact is that almost any boiler can be tuned to about 90% or better by under-firing it and tuning it to maximum efficiency. The first result is to reduce the stack temperature enough that it will most assuredly cause condensing in a stack not suited for this. That is why as a rule of thumb in non-condensing boilers the stack temperature needs to be maintained to at least 350° F to avoid this and the results of stack rot from the acidity of the gases. More commonly they are tuned at 450° F. I emphasize again that; the controlling factor in the design of the non-condensing boiler is the stack temperature, and not total efficiencies. So, this confining factor of high stack temperatures controls the design of most heating systems in the US. And to make matters worse, the longer the stack, the more heat it looses, so the higher the exiting flue gas temperatures need to be at the boiler.

Along with the above design factors, boilers have been in the past and still are to a great extent oversized. This also leads to greater inefficiencies. For example, a typical cast iron boiler starts at a very low efficiency and slowly works its way higher as the massive cast iron heat exchanger absorbs heat from the burner. This can take a while as these boilers can contain from 20 to 30 gallons of water. On moderate heating days, the typical boiler must fully heat up before it can begin heating the home. If the home only needs a little heat, the boiler will soon shut down, the boiler cools off, and the leftover heat goes up the chimney. Next time the home needs heat, the boiler has to re-fire and heat up all over again. On a 30-degree day, that boiler is assuredly operating well below its AFUE rating. And since most boilers are over-sized the discrepancy can be even greater. To add even more inefficiencies to these clunkers is the fact that most of them had internal heating coils for domestic on demand hot water. This causes even more short-cycling. See the discussion DHW (domestic hot water). To make matters worse, the large cast iron boilers must be protected from boiler-shock. This happens when overly cool water returns to a hot boiler. It is a thermal shock that can crack the cast iron.

<top>

The FCX Condensing Boiler

The FCX operates at the lower temperatures that promote condensing. The low mass of the FCX, (it only holds 4 gallons of water), allows it to come up to temperature quickly and run efficiently from the start. This translates to faster start up times where the heat immediately is transferred to the emitter. It is designed to short cycle. In fact, the burner comes standard with a fuel line heater which is integrated into the nozzle assembly and the boiler will not fire until the fuel temperature is above 130 degrees insuring an efficient burn from the start. A further note is that a condensing boiler is more efficient on start-up as the return water to the condenser is cooler which promotes more condensing. Measured efficiencies of 98% on start-up are not unusual.

The FCX has a primary welded steel heat exchanger, so it is not susceptible to “boiler shock” from cold-water return. In fact, for the FCX, the colder the return water the better. Next is the secondary stainless steel heat exchanger (this is the condenser through which the flue gases pass before entering the stack). As these flue gases pass through the condenser prior to entering the stack, the return-water from the heat emitter cools them and a portion of the water vapor is reduced to liquid giving up the latent heat of vaporization to the water in the boiler. This means that the boiler “makes water” which must be collected and disposed of. This slightly acidic condensate can then be drained with the rest of the household wastewater. In a normal residential application, the basic nature of household waste is more than adequate to neutralize it. However, it can be neutralized if desired or needed. Because the condensing process lowers stack temperatures to such a great degree, while further increasing efficiency, it allows the use of alternate stack materials. The stack temperatures for condensing boilers are so low that plastic is the standard to be used and is zero clearance rated. This greatly reduces building time and cost.

In addition, the FCX is a counter flow boiler. This means that the flue gasses flow in the opposite direction as the water being heated. This is by far the most efficient way to transfer heat, and no conventual boilers use this system as it promotes condensing which is not allowable in the conventual boiler.

The FCX has two supply and return circuits, and comes complete with a built-in mixing valve, expansion tank and pump for the mixed circuit. This mixed circuit is essentially “plug and play” and is ready to connect to your manifolds. The secondary “hot” (unmixed) circuit is for the purpose of heating domestic water through an indirect DHW tank or used in other “hot” applications such as a baseboard or unit heaters. Its core temperature can be adjusted from 120° to 158°, but contrary to industry myth, 120° to 130° is quite adequate to produce DHW with a high efficiency indirect heater.

A major note of interest that goes beyond the “out of the box” installation, is that once the threshold of handling the condensate is surpassed, anything that reduces return water temperatures and stack temperatures increases efficiency. This means that further heat exchangers can be added which further lower stack temperatures such as HRV air pre-heaters, DHW water pre-heaters, plastic stack robbers, etc. The efficiency gain is as much from reduced flue gas temperatures as from the condensing aspect. I have documented flue temperature reductions to 80° and further reductions can be made through innovations such as geo-thermal combined systems to further lower stack temperatures. Controls are also a major factor in efficiency. This is discussed in detail on the Installation page.

One further note: it cannot be stressed enough that even though this is a condensing boiler, the basic operation is no different than that of any other boiler, other than having a stainless steel after condenser.

<top>

The FCX in Non-Condensing Mode

It should now be apparent from reading this and other sections that the FCX or any condensing boiler runs best when return water temperatures are low enough to promote condensing. This does not mean that the FCX cannot run at higher temperatures. In fact, the FCX will still out perform a non-condensing boiler simply because it has more heat exchanger. And you most likely will get condensing in the stack because it is further from the boiler and has a chance to cool more. But you need some condensing in the condenser in order to keep it clean as the water washes the tubes. So, if it is the case that you must run in non-condensing mode for a significant time or continually, the condenser will need flushing more. However, chances are you will not have to run in this mode for any significant time. See the Brookhaven National Lab’s study using the FCX in a baseboard study. Also see the suitability section for a discussion of other options. The Maintenance section discusses this also.

<top>

Efficiency and Tuning of the FCX

The principles of tuning a condensing boiler are essentially the same as those for a conventional non-condensing boiler. However, the adjustments are much more critical with the condensing boiler. Please examine the following diagrams that show the relationship of the various factors of combustion:

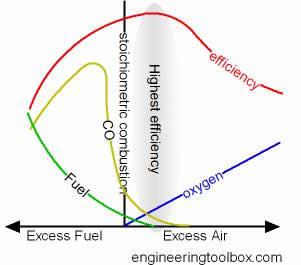

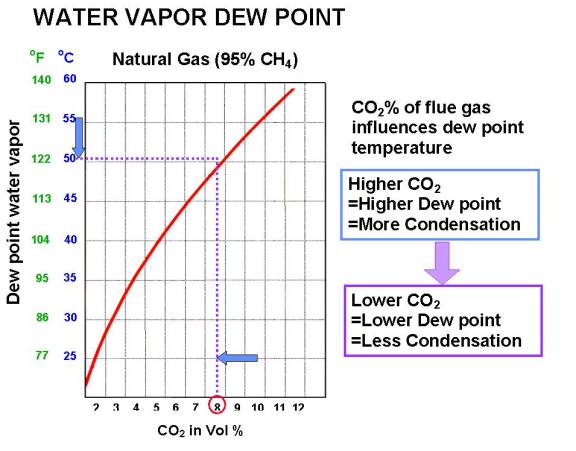

The top graph shows that there is a range in the air setting that gives the greatest efficiency, while the bottom graph shows the relationship between excess air and CO2 levels. What is not shown is that the level of CO2 is an indicator of the dew point of the combustion gasses. What this means is the higher the CO2 level, the less the flue gasses need to be cooled to condense. I.E. the more efficient the boiler runs. We accomplish this by reducing excess air levels to the minimum.

However as can be seen there is a practical level at which CO2 can be set because at some point as excess air is decreased CO levels increase. This results in unburned carbon (smoke). Therefore, for maximum efficiency a condensing boiler must be carefully tuned. The following will outline the principles involved.

The above diagram is taken from an Ashrae Presentation on Condensing Technology by Jim Cook, in November 2005. It deals almost exclusively with natural gas, but the principles are the same as that for oil. The main difference is that the highest temperature that oil condenses is about 115 degrees; whereas natural gas condenses at 131 degrees. This means that gas is more readily condensable, so temperature control is even more critical for oil than gas. As can be seen, the higher the CO2, the higher to dew point, which means more condensation, which means higher efficiency. The following link will download the entire presentation. AshraeCondensingTechnology.pdf

Flue Gas Loss with Oil Combustion

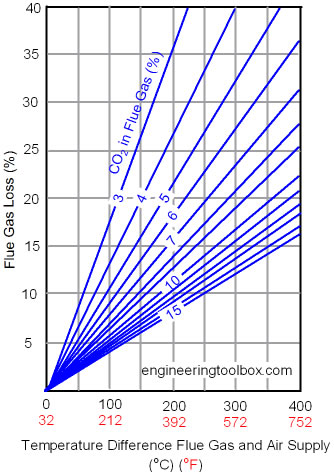

The relation between temperature difference in flue gas and supply air, the CO2 concentration in the flue gas, and the efficiency loss in the flue gas oil combustion, is expressed below:

Example - Oil Combustion and Heat Loss in the Flue Gas

If the temperature difference between the flue gas leaving a boiler and the ambient supply temperature is 450-60=390 oF, and the carbon dioxide measured in the flue gas is 10% - then, from the diagram above the flue gas loss can be estimated to approximately 11%.

<top>

Spin on efficiency

Seasonal Efficiency is what counts. Some sellers of high efficiency non-condensing boilers go through mathematical and statistical gyrations to try to convince you that their boilers are the most efficient in the world do to their sophisticated computerized controls and other devices. But here are the facts: If the heat goes up the chimney, it’s gone. So…

- Start with the most efficient burn technology that exists (condensing).

- Counter-flow heat exchange.

- Add the features and controls to optimize your system.

The Bottom Line – Items to Consider

- So consider the differences of 450° flue gas temperatures for a tall stack (all lost to the great outside) or an exit temperature of 80° (enhanced heat removal) for an equivalent plastic stack.

- In a conventional boiler once the heat goes out the stack, it is lost and is gone forever.

- A condensing boiler can produce fuel savings of 30% to 50% over conventional boilers.

- In a condensing boiler every degree you lower the stack temperature is $ in your pocket.

- Years ago when fuel was $0.75 a gallon did it matter much? How about now? How about 5 years from now?

<top>

References

http://www.engineeringtoolbox.com/boiler-combustion-efficiency-d_271.html

http://books.google.com/books?id=zoINfDkh2QYC&pg=PA73#v=onepage&q=&f=false

http://www.pollutionengineering.com/Articles/Casebook/5ae44140bdd68010VgnVCM100000f932a8c0

Q.E.D.

<top>